Practical Datacom Lasers

Lumentum shorts shall be burnt to a crisp.

Irrational Analysis is heavily invested in the semiconductor industry.

Positions will change over time and are regularly updated.

Opinions are authors own and do not represent past, present, and/or future employers.

All content published on this newsletter is based on public information and independent research conducted since 2011.

This newsletter is not financial advice and readers should always do their own research before investing in any security.

Feel free to contact me via email at: irrational_analysis@proton.me

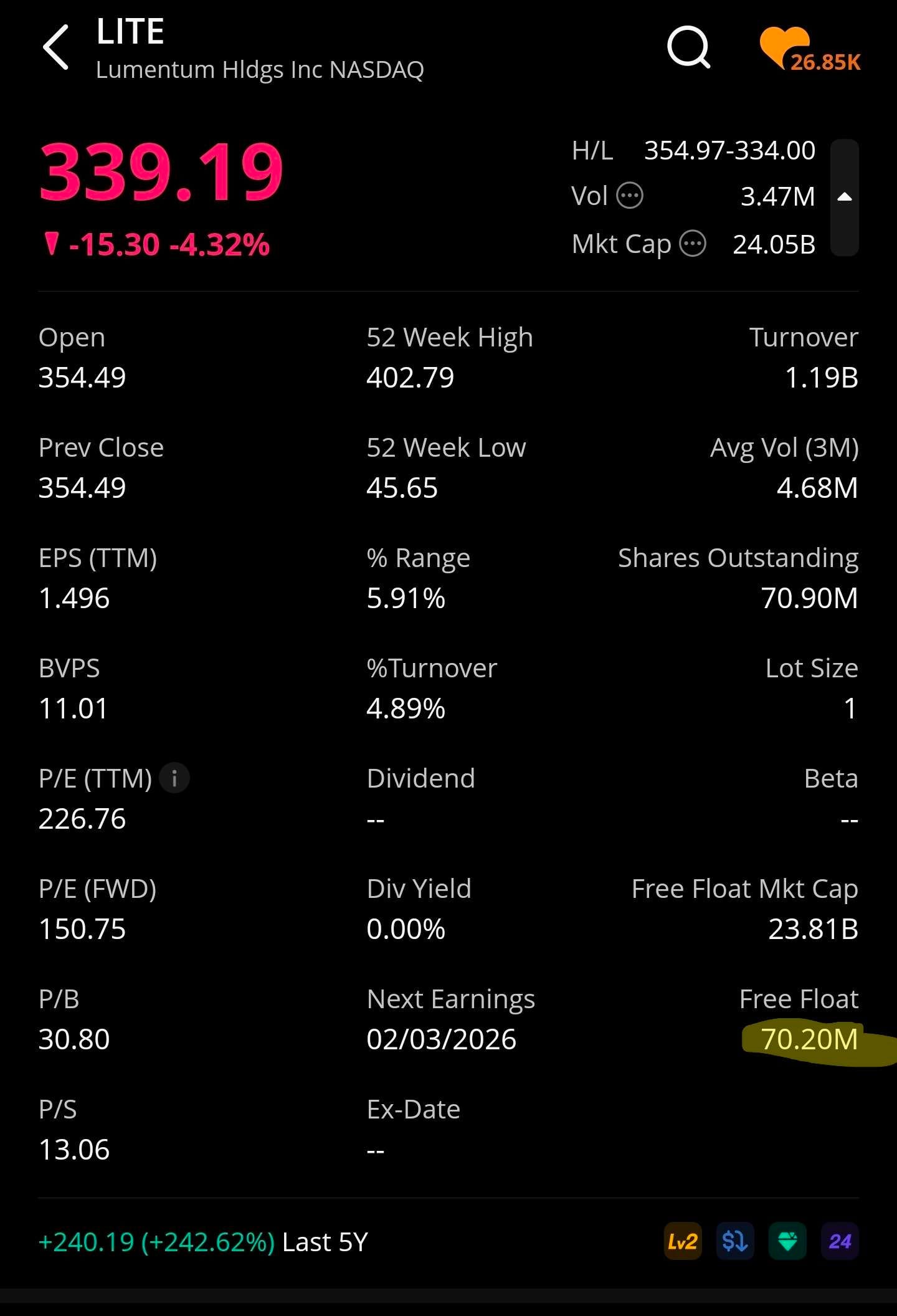

At the time of writing, Lumentum ( LITE 0.00%↑ ) has approximately 17% short interest.

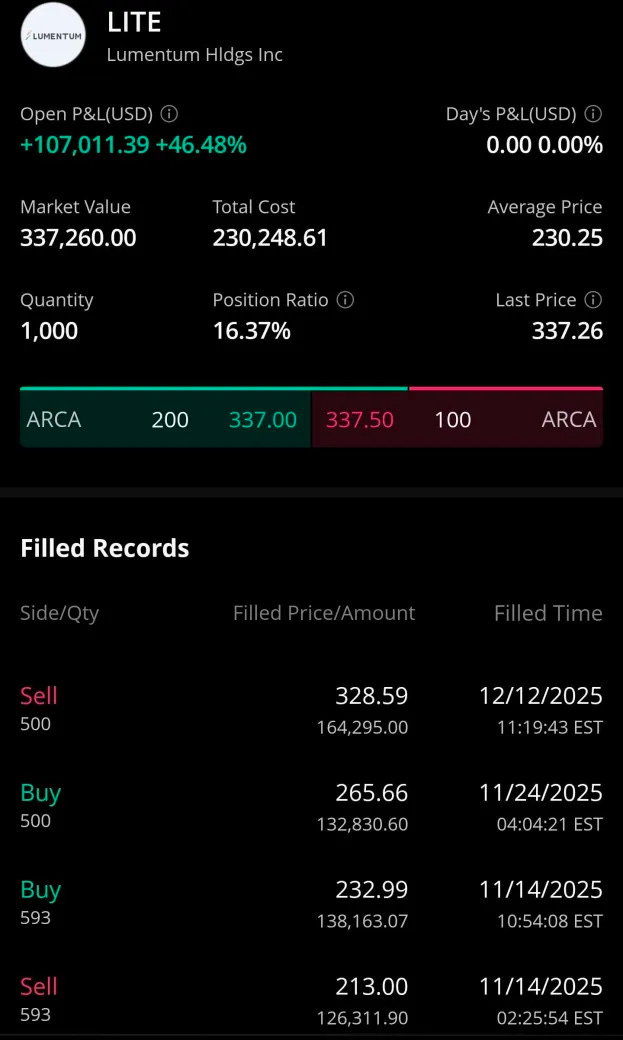

I also own a lot of Lumentum stock. It is #2 position (behind Intel) in the trading account.

And to answer the question that keeps getting asked, I’m not selling Intel. Nothing has changed. The post from a few days ago that roasted Intel Products has nothing to do with my investment thesis. I consider Intel Products to be a long-term zero anyway.

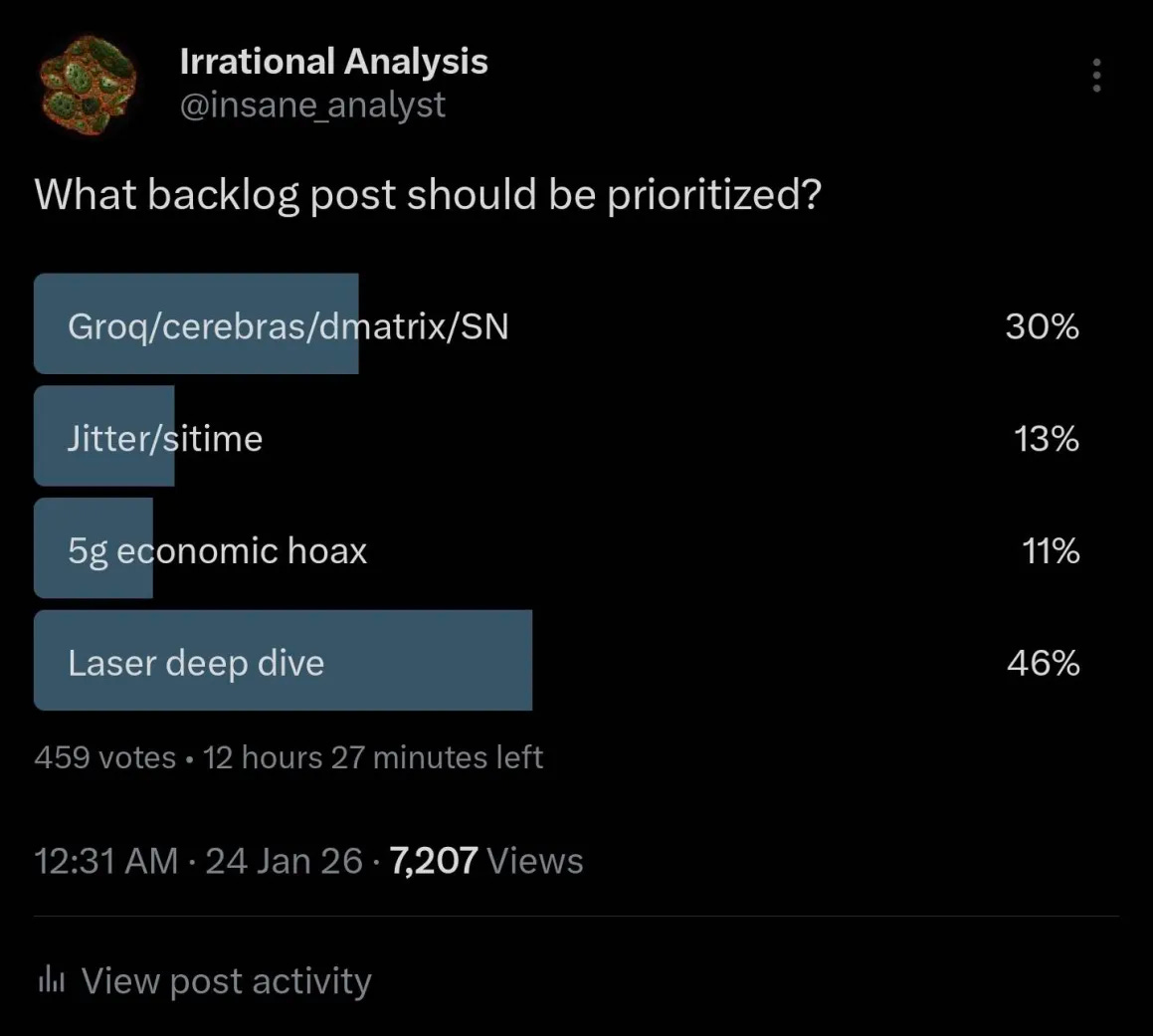

Also a lot of general interest in lasers.

I encourage all institutional investors who read this to short LITE 0.00%↑ to make the incoming squeeze more entertaining.

Invert me, I dare you.

You know my biases.

The free market shall decide who is right.

Contents:

Two Types of Datacom Lasers

VCSEL

DFB

Modern Market Landscape

How Continuous-Wave (CW) Lasers Effect Communication Systems

Math Detour: Dirac Delta Function

Mixing in Communication Systems

CW Lasers Want to be a Dirac Delta

Linewidth and Relative-Intensity Noise (RIN)

Side Modes and Mode Hops

System Cost

Laser Noise Primary Factors

Laser Power

Electrical Driver Quality

Thermal Control and Stability

Laser Construction/Design, Process Tech, and Packaging

Public Information from Lumentum

[1] Two Types of Datacom Lasers

There are many types of lasers, but these are the only two that matter for data communication. Industrial market and other niche markets have other lasers. Skipping those in the interest of time.

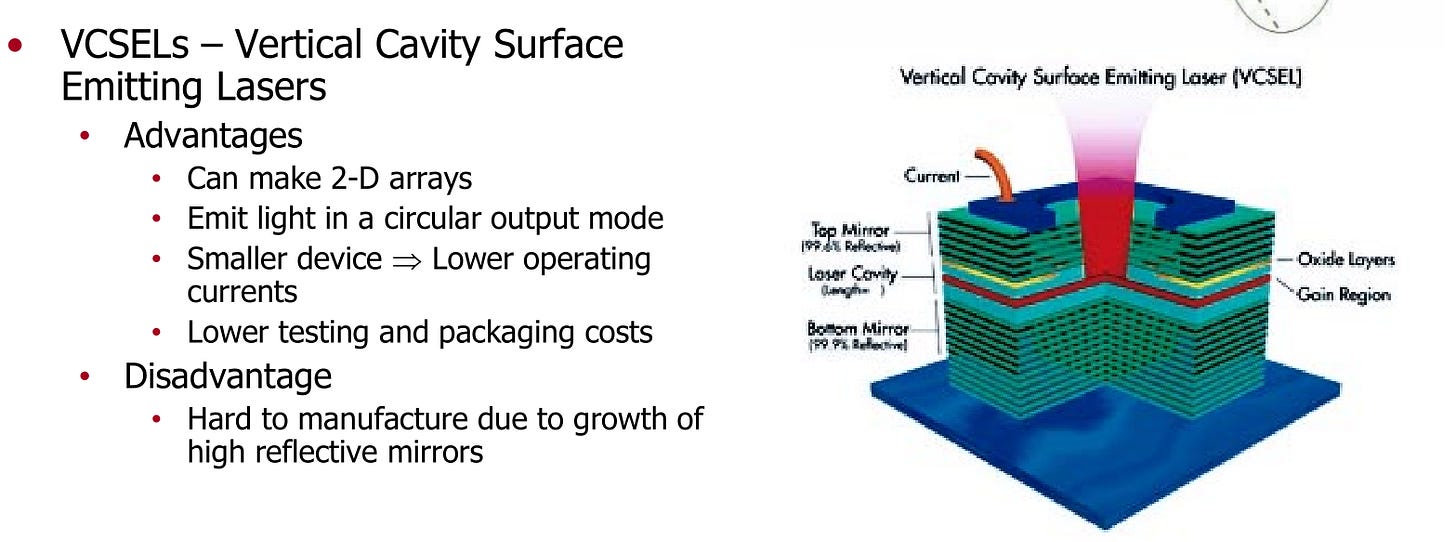

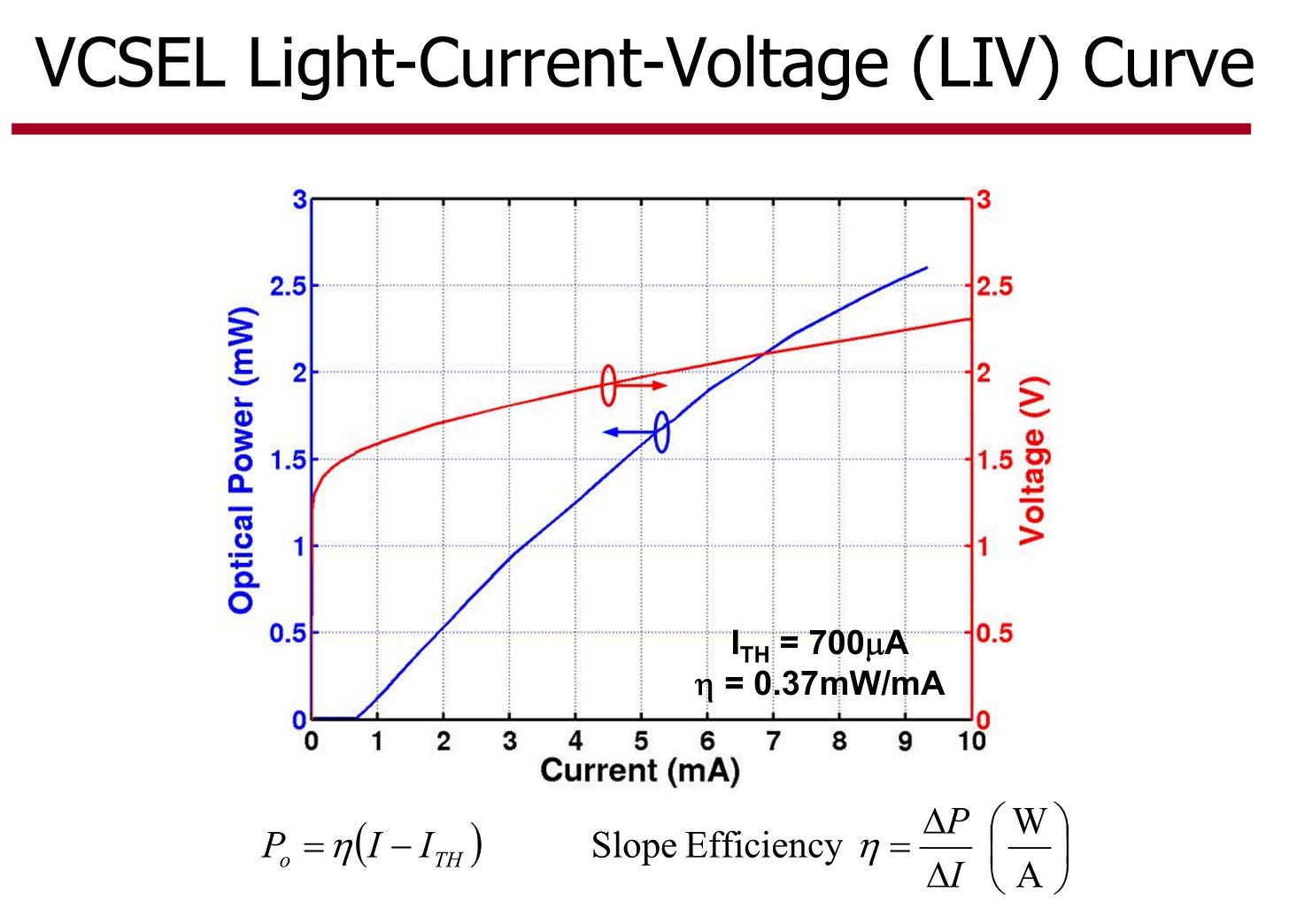

[1.a] VCSEL

This is what a VCSEL looks like.

light comes out of the gain region vertically.

In general, VCSEL’s have very low optical output power.

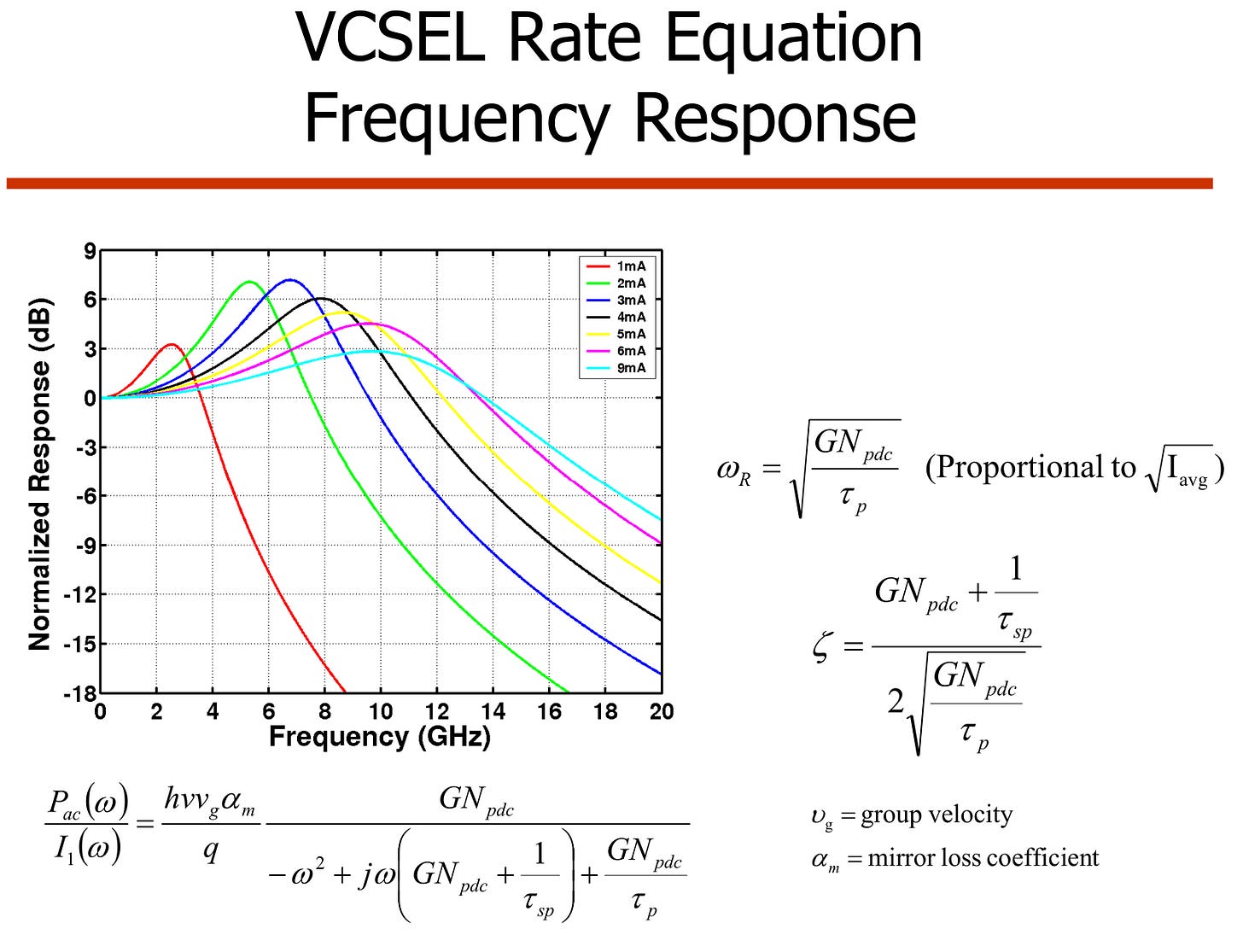

They are also bandwidth limited.

Severely bandwidth limited.

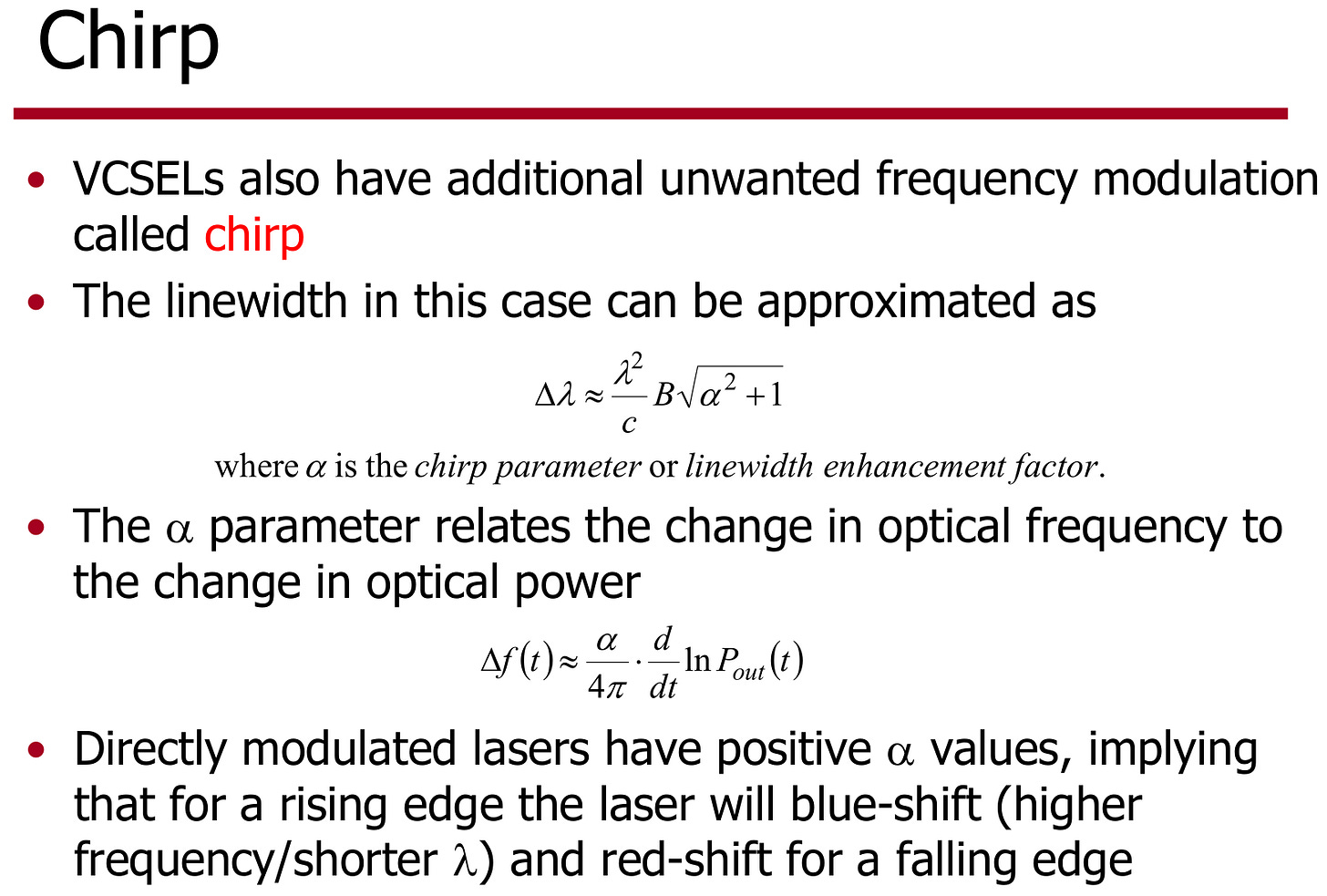

Because VCSEL systems are directly modulated (power supply is the SerDes itself), they suffer from something the optical people call “chirp”.

This is essentially a correlated phase noise and amplitude non-linearity impairment.

In short, VCSEL has a lot of problems but one key benefit.

CHEAP

SO CHEAP

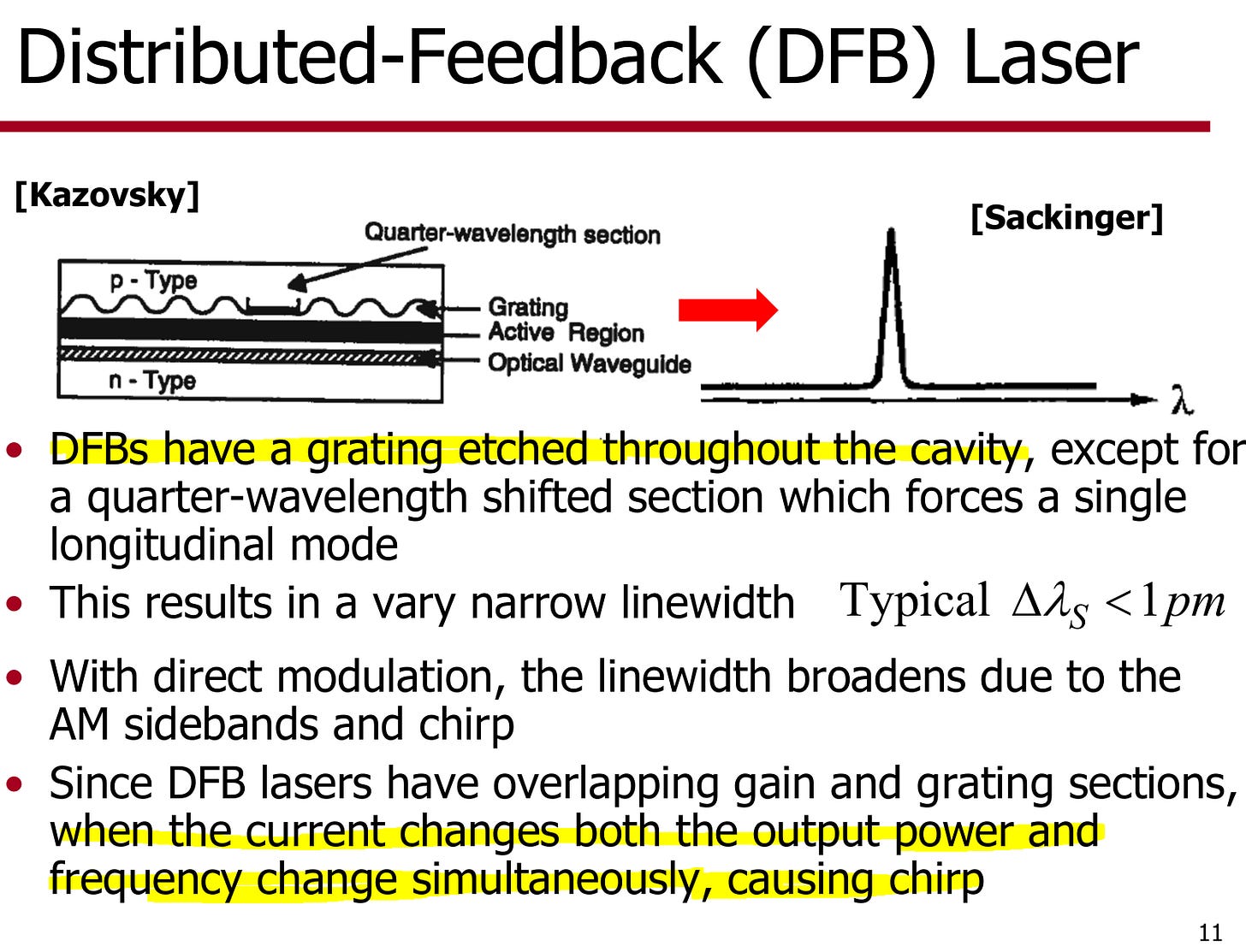

[1.b] DFB

Distributed-Feedback lasers have light coming out in parallel to the gain medium.

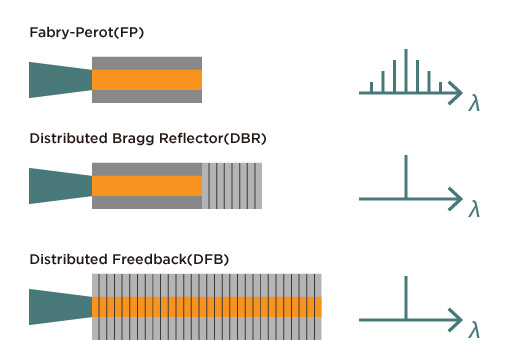

The best way to understand why you need feedback is to check what things look like without feedback…

No feedback means Fabry-Perot laser, and lots of ugly side-modes. More on why side modes are bad in a bit.

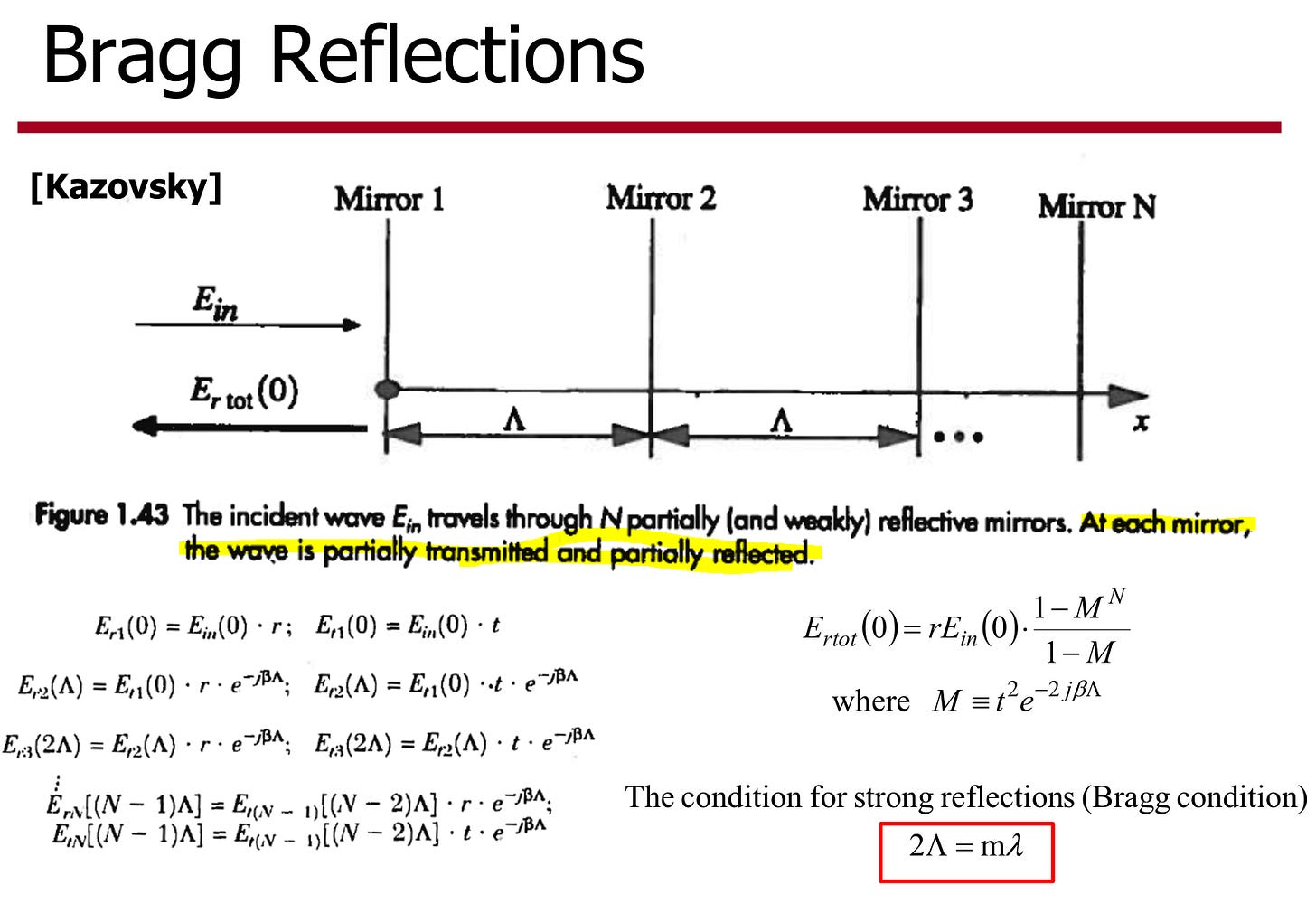

If you have some mirrors at the end of the gain medium, you get a Distributed Bragg Reflector. Much better.

If you place the mirrors in the gain medium itself, you get a DFB. Best performance but much more difficult to make.

Replace “grating” with “lots of tiny mirrors”.

[2] Modern Market Landscape

I have a longer post on this….

In short:

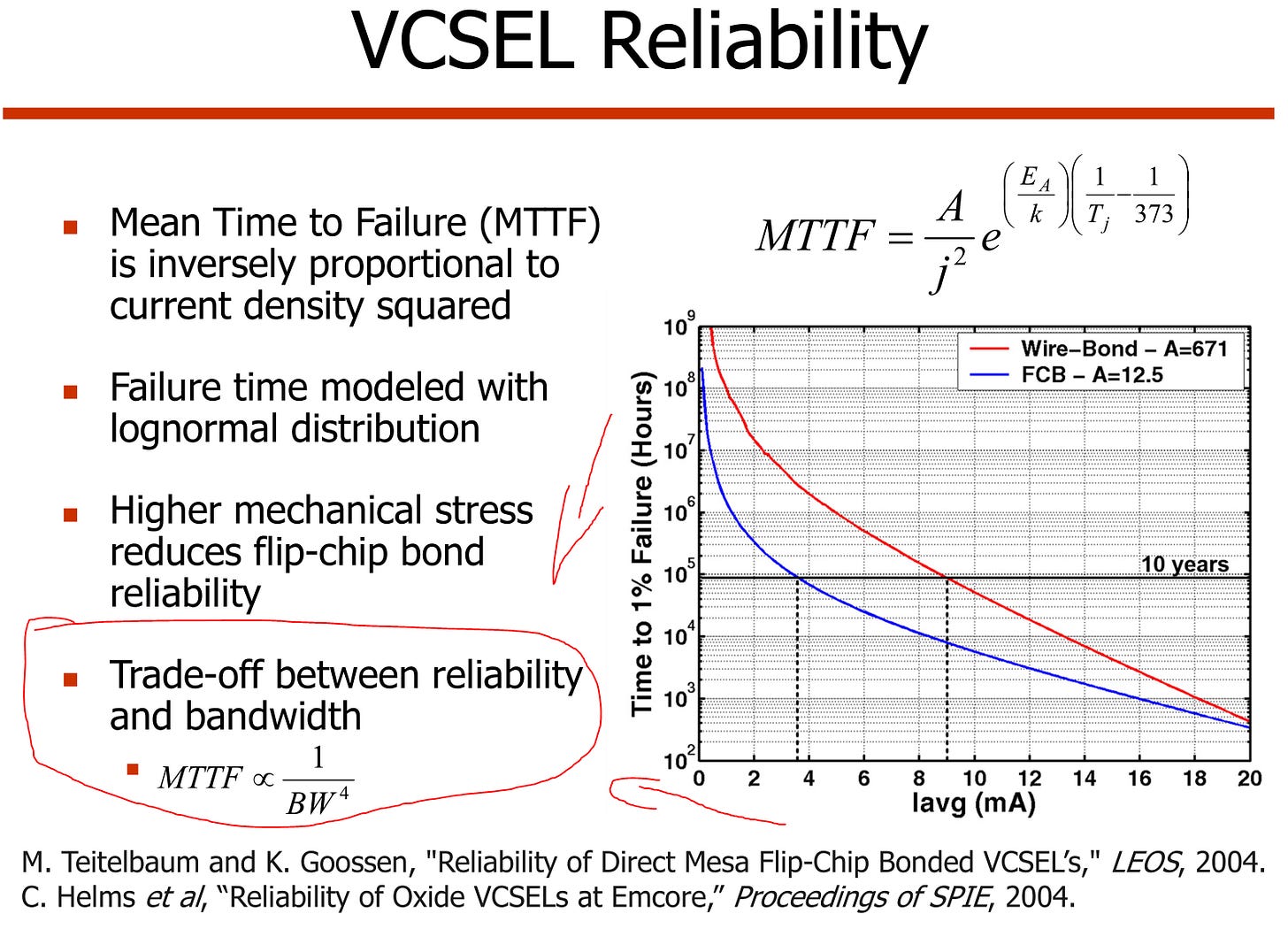

VCSEL

Dominant for 800G transceivers and below.

Reliability issues make tech unviable for 200G/lane (1.6T) tranceivers.

Coherent and Broadcom have publicly shown interesting VCSEL-based CPO tech. Arrays of 100G-speed VCSEL.

VCSEL may have a role in niche CPO but I think it’s the end of the road.

DFB

Dominant technology for everywhere VCSEL fails.

All EML have DFB inside.

All SiPho (ring modulators, MZI, EAM) need DFB as an external light source.

[3] How Continuous-Wave (CW) Lasers Effect Communication Systems

To understand how CW (DFB) lasers impact communication systems, we but take a math detour.

Eat your broccoli finance people. A little math wont kill you.

[3.a] Math Detour: Dirac Delta Function

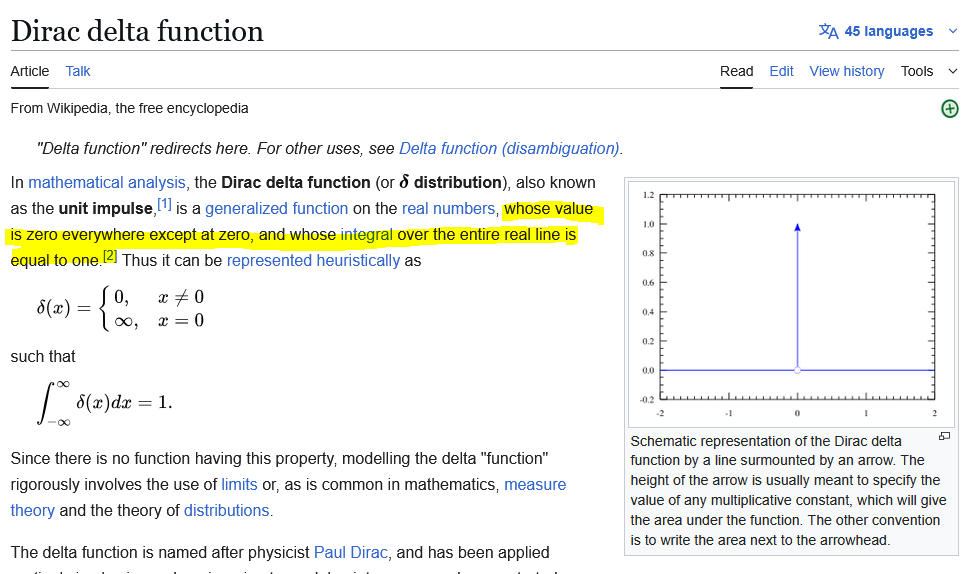

https://en.wikipedia.org/wiki/Dirac_delta_function

Dirac delta function is a strange concept.

An infinitely thin line that has an area of 1.

This does not exist in the real world but it is very useful for systems modeling and digital signal processing.

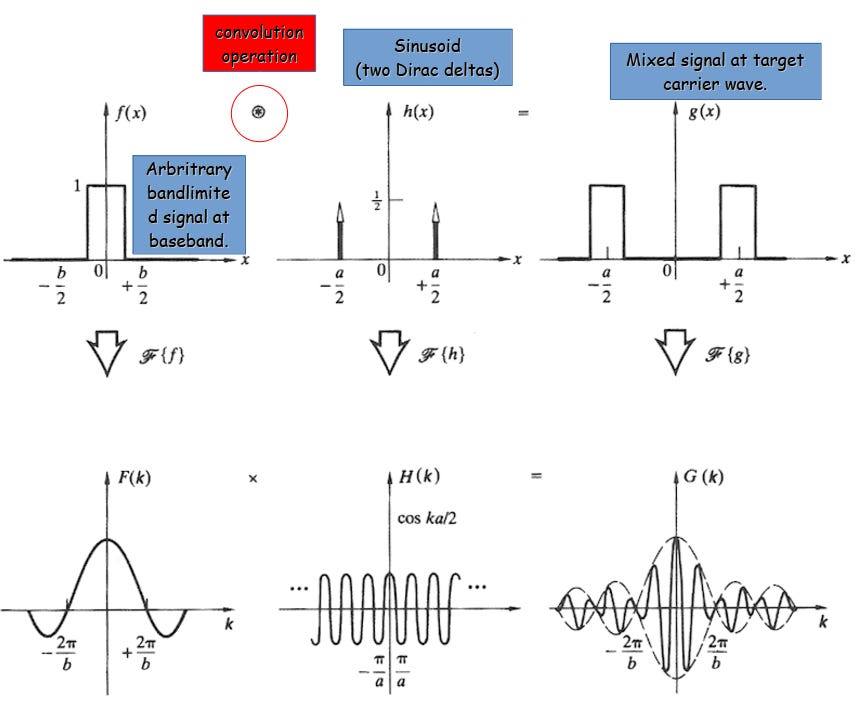

[3.b] Mixing in Communication Systems

You use WiFi right? 2.4 GHz… 5GHz…

How is the electrical signal moved to those high frequencies?

The answer is mixing. Take the baseband, band-limited signal, multiply it by a sinusoid, and you up-mix.

All wireless and (externally modulated) optical communications work in this way. There exists a “carrier” wave that takes your data on a magical journey.

[3.c] CW Lasers Want to be a Dirac Delta

CW/DFB lasers desperately want to be Dirac Deltas, but they will never live up to these unrealistic expectations.

If a laser is perfect, it has zero linewidth and zero relative-intensity noise. This is impossible so let’s go back to the real world.

[3.d] Linewidth and Relative-Intensity Noise (RIN)

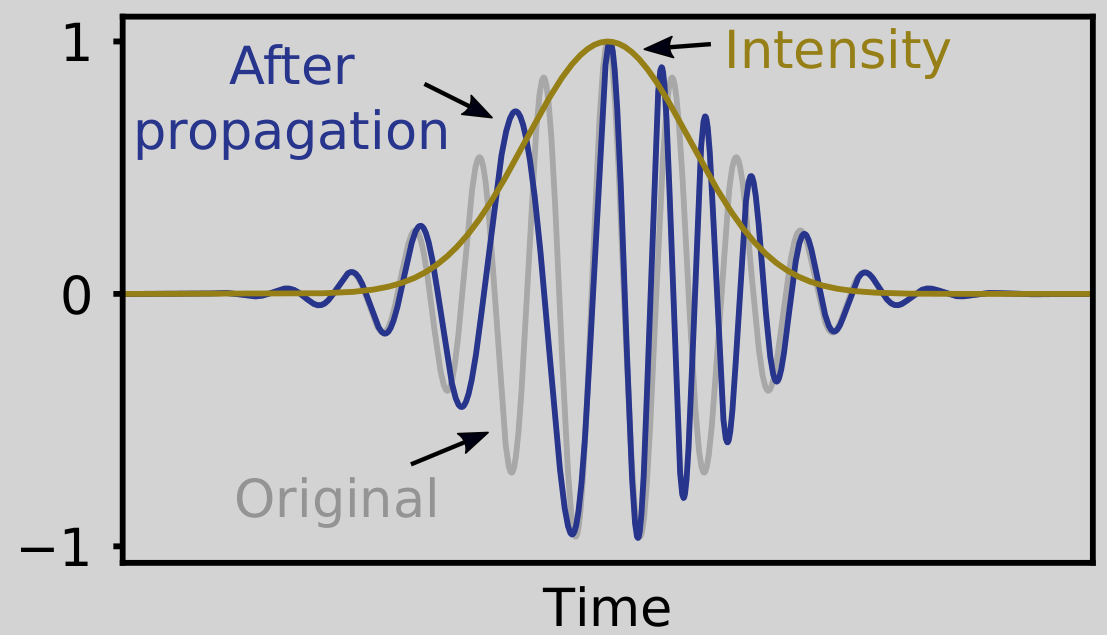

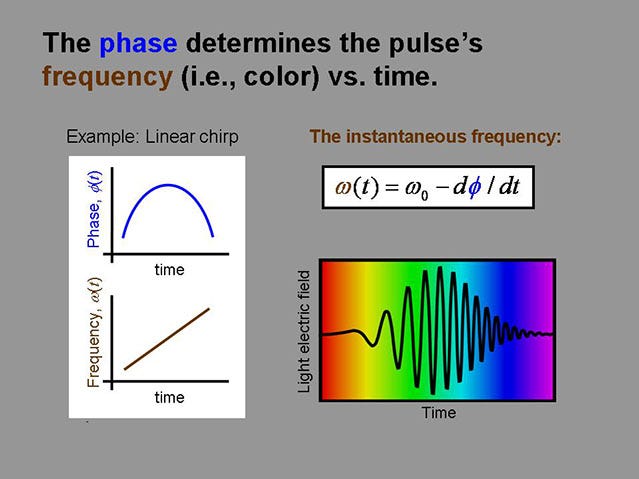

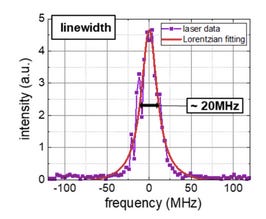

Linewidth is a measurement of how “sharp” a laser is.

The simple definition is “how wide the laser is at half power (3 dB from peak)”.

Unfortunately, lasers are constantly moving around due to electrical noise, driver fluctuations, and thermal noise. More on this in section [4].

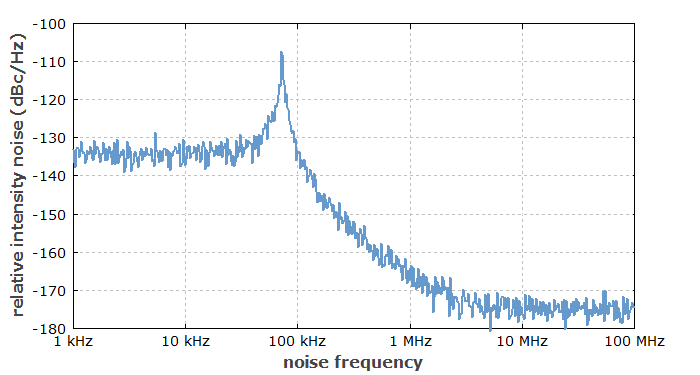

Relative-intensity noise (RIN) is amplitude noise.

How much (and at what frequency) the failed Dirac delta wiggle up and down.

The measurement typically looks something like this.

Typically, people define RIN specification as the integration of the spectrum from some starting frequency (1 MHz, 10 MHz) to the Nyquist frequency of their system. Thus, RIN is a data rate-dependent specification.

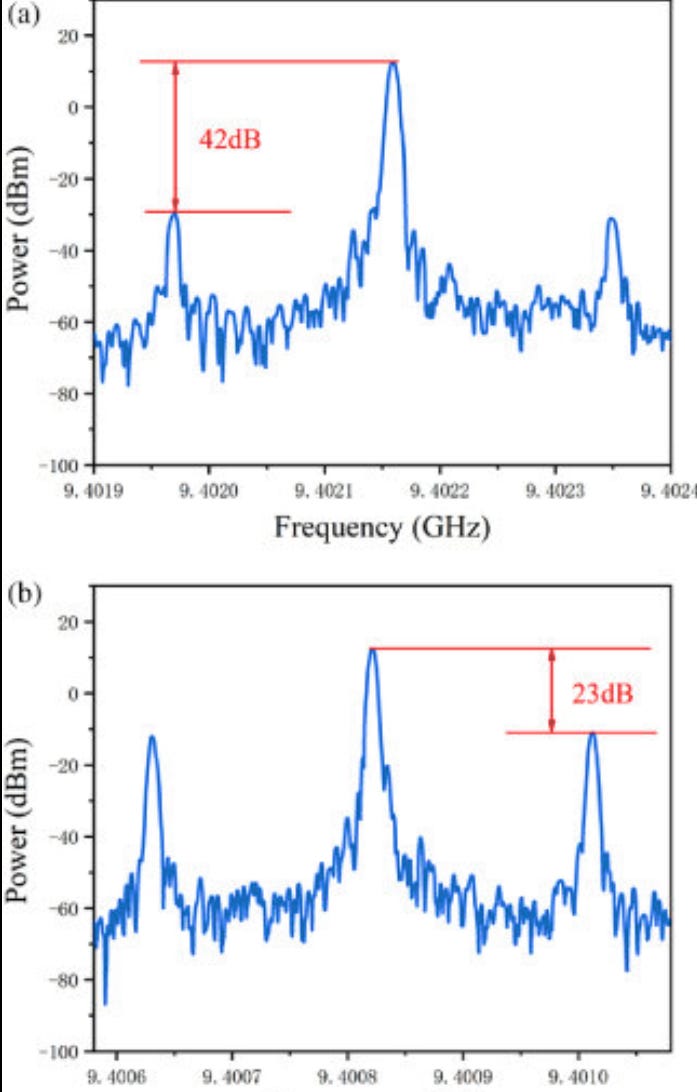

[3.e] Side Modes and Mode Hops

Side-modes are extra bits that were not filtered out by the gratings inside a DFB.

From a math perspective, these are extra (ugly) Dirac deltas that will manifest as reflections in the communication system. A simple FFE EQ can fix these is some cases. In other cases, your link goes to shit.

The more worrying aspect of side-modes is mode-hopping.

Lasers have a habit of wanting to jump around in frequency…. instantaneously.

The vast majority of transceiver link flaps come from laser mode hops.

Poor side-mode suppression ratio of a DFB indicates a high risk of mode-hops, link-flaps, pain, and suffering.

[3.f] System Cost

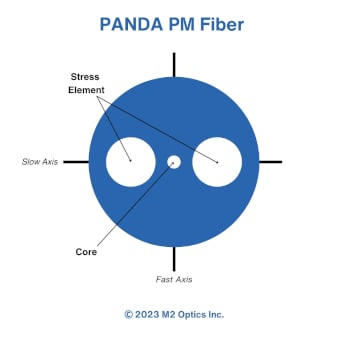

This is what most polarization-maintaining fibers look like.

It’s a cute panda!

The resemblance is striking, is it not?

No?

Yea that’s what I thought. Optics world is weird.

The two extra big circles are to mechanically stress the fiber to make sure light stays in the same orientation.

In general, laser polarization needs to be maintained from the laser source to the modulator.

PM fibers are expensive.

Fiber attach is expensive and a yield issue.

Nobody fucking wants more PM fiber than is absolutely necessary.

This market reality places enormous pressure on laser manufactures to push optical power per laser as high as possible, despite the challenges that come with this…

[4] Laser Noise Primary Factors

You should know understand where laser noise comes from, so let’s take a look at the factors that make it worse!

[4.a] Laser Power

More power more noise due to many factors. From electrical driver to thermal noise, to imperfections in gratings being amplified, to material defects in the layers of the laser itself.

More power, more difficult. A LOT MORE DIFFICULT.

[4.b] Electrical Driver Quality

The electrical power to the laser needs to be super clean. Any ripple or noise from the driver gets amplified by the laser in the optical domain.

Requirements for laser drivers far exceed any switching regulator VRM in even the highest power GPU/XPU. Spamming more switching regulators does not work. You cannot throw money at the problem.

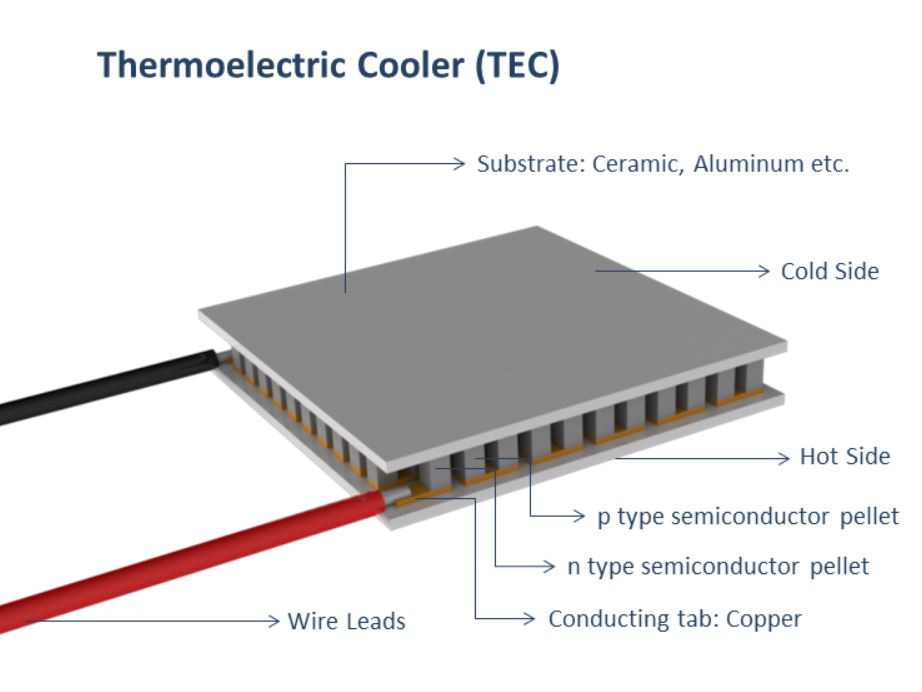

[4.c] Thermal Control and Stability

Laser diodes are extremely temperature sensitive. To optimize performance, you need to keep the temperature at a specific point.

Each laser has a different sweep-stop temperature.

Suppose a DFB has been designed for operation at 40C.

A particular unit might want to be at 41.85C +/- (less than 0.01 C deviation)

How do you get this level of precision and stability?

Thermoelectric cooler. (TEC)

In principal, this is a solid-state (no mechanical parts) device that an inefficient process to move heat.

TEC has a cold-side and a hot-side. The external environment (air cooled transceiver fin cage, liquid cooled cold-plate, whatever) is connected to the hot side, the laser to the cold side.

Remember, temperature fluctuations ruin everything. Wavelength stability. RIN. Linewidth. Mode hops. EVERYTHING.

[4.d] Laser Construction/Design, Process Tech, and Packaging

Linewidth and RIN performance heavily depend on the intrinsic “quality” of the manufacturing process.

If the packaging is bad, thermals will move around and impedance mismatch in the package itself can ruin an otherwise great driver and PCB design.

If there are uniformity problems in the epitaxy process, everything goes to shit.

If the grating and coupling optical path design is bad, lol you fucked.

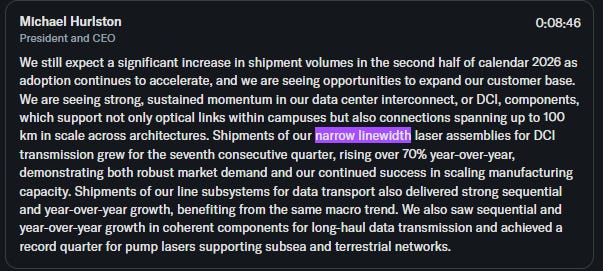

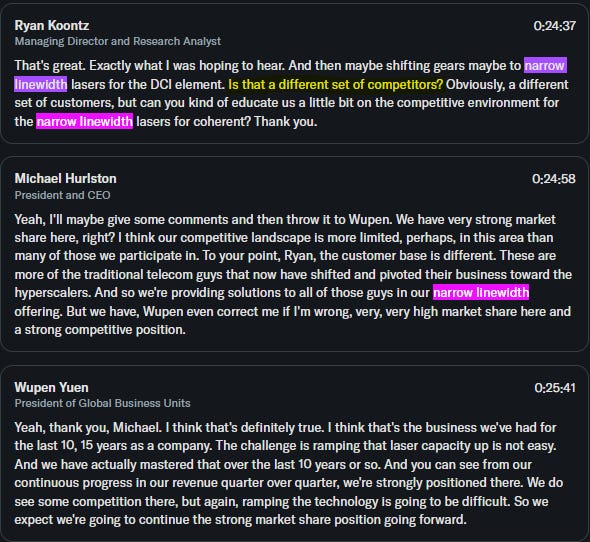

[5] Public Information from Lumentum

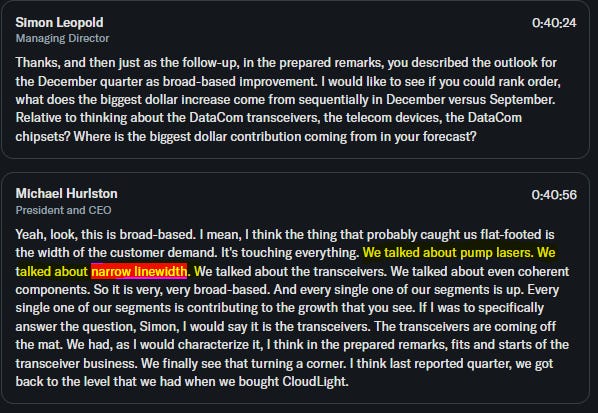

Let’s start with the most recent earnings call transcript.

What if I told you there are almost no competitors for high-power, narrow-linewidth DFB?

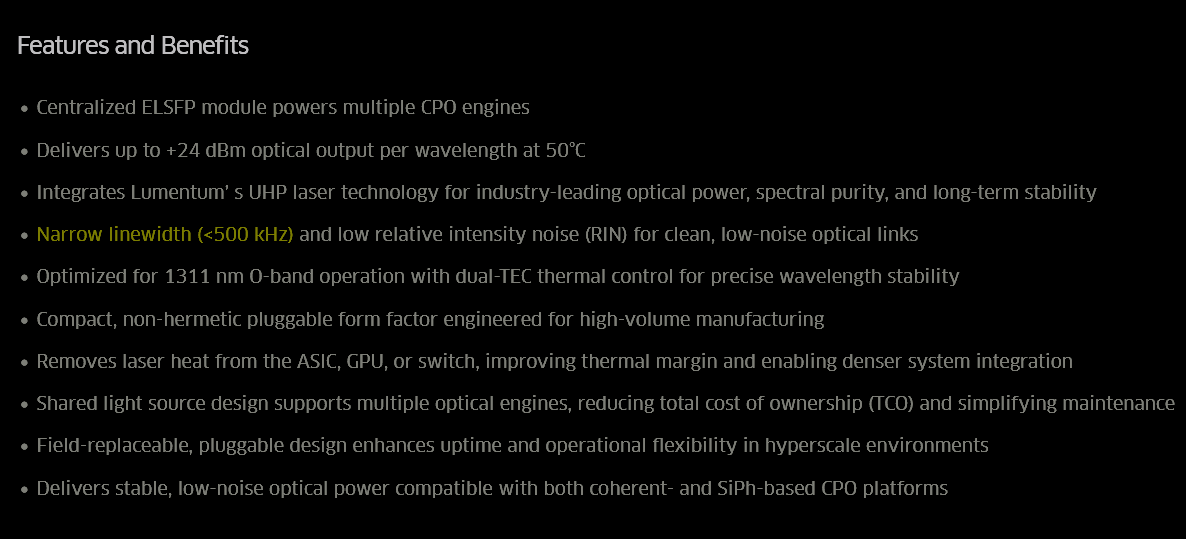

Let’s take a look at Lumentum’s website.

https://www.lumentum.com/en/products/external-laser-source-els-module-ultra-high-power-laser

Go around to the websites of Lumentum competitors.

TRY TO FIND ANY LUMENTUM COMPETITOR MAKEING PUBLIC CLAIMS ON LASER LINEWIDTH FOR HIGH-POWER (300mW+) DFB AT O-BAND.

I have no idea what any of this means and have no intention of doing my own research.

But i like star wars and IA likes $LITE so I am full aping my bank account in Lumentum. YOLO lol

Wonder if it’s worth playing the InP angle here through Aixtron for tooling. Depends on how high demand drives CapEx for tooling.